Product Description

Chockfast Orange PR-610TCF c/w Hardener (6.8 kg/set). Maker: ITW Philadelphia Resins

PRODUCT DESCRIPTION:

CHOCKFAST ORANGE (PR-610TCF) is a specially formulated 100% solids, two component inert filled casting compound developed for use as a chocking or grouting material. CHOCKFAST is designed to withstand severe marine and industrial environments involving a high degree of both physical and thermal shock. The compound is non-shrinking and has very high impact and compressive strength.

Years of successful in-service experience have shown the use of PR-610TCF to be a far superior yet less expensive method of establishing and permanently retaining precise equipment alignment under extreme conditions.

PR-610TCF is approved or accepted for its intended marine use by American Bureau of Shipping, Lloyd's Register, Bureau Veritas, Det Norske Veritas, Germanischer Lloyd and most other major regulatory agencies worldwide.

USE & BENEFITS:

CHOCKFAST ORANGE was developed as a chocking or grouting compound for use under marine main propulsion machinery in depths of ½” to 4” (12mm to 100mm). The compound is used under diesel and gas engines, reduction gears, generators, compressors, pumps, bearing blocks, crane rails and numerous other applications.

PR-610TCF requires no special tools or special skills as does chocking with steel. When cast, CHOCKFAST ORANGE flows readily into the chock area filling voids and conforming to all irregularities. This eliminates the machining of base plates or foundations for a perfectly fitted chock.

DESIGN CONSIDERATIONS:

For design considerations and application details please request Bulletin No. 692 for Marine and 642 for Industrial applications or contact ITW Philadelphia Resins' Engineering Services Department.

APPLICATION INSTRUCTIONS:

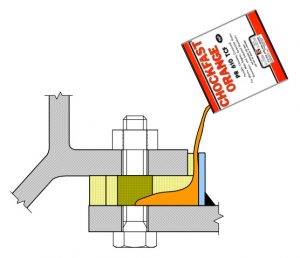

Using open-cell foam damming material, build a dam around 3 sides of the area to be chocked. Wrap the anchor bolt with tape so the Chockfast will not stick to it, Install a metal dam along the front of the chock approximately ½” to ¾” (12mm to 18mm) from the mounting flange. Seal the flange with strip caulking, or Silicone to prevent leaks. Install foam in the overpour area to the top of the mounting flange to prevent the Chockfast from leaking.

Mix the Chockfast as directed on the can. See technical Bulletin #665 to determine the proper amount of hardener to use. Slowly pour the Chockfast into one end of the overpour area and allow it to flow across and under the mounting flange.

PHYSICAL PROPERTIES

| COMPRESSIVE STRENGTH | 19,000 psi (131 MPa) | ASTM D695 MOD |

| COMPRESSIVE MODULUS OF ELASTICITY | 533,000 psi (3674,91 MPa) | ASTM D695 MOD |

| LINEAR SHRINKAGE | 0.0002 in/in (0.0002 mm/mm) or 0.02% | ASTM D2566 |

| COEFFICIENT OF LINEAR THERMAL EXPANSION |

17.1 x 10-6/F° @ 32°F to 140°F(30.8 x 10-6/C° @ 0°C to 60°C) |

ASTM D696 |

| FLEXURAL STRENGTH | 7,615 psi (52,50 MPa) | ASTM C580 |

| FLEXURAL MODULUS OF ELASTICITY | 8.6 x 105 psi (5929,49 MPa) | ASTM C580 |

| TENSILE STRENGTH | 4,970 psi (34,27 MPa) | ASTM D638 |

| SHEAR STRENGTH | 5,400 psi (37,23 MPa) |

FED-STD-406 (Method 1041) |

| IZOD IMPACT STRENGTH | 6 in.lbs/in. (0.27 N.m/cm) | ASTM D256 |

| SHOCK RESISTANCE |

Pass MIL-S-901C (Navy) High ImpactShock Test, Grade A, Type A,Class 1 |

|

| THERMAL SHOCK | Pass 0°F to 212°F (-18°C to 100°C) | ASTM D746 |

| VIBRATION | Meets MIL-STD-167 | |

| FIRE RESISTANCE | Self-extinguishing | ASTM D635 |

| SPECIFIC GRAVITY | 1.58 | |

| BARCOL HARDNESS | 40+ fully cured – 35 minimum | ASTM D2583 |

PRODUCT INFORMATION

| UNIT COVERAGE |

Small Unit: 120 cu.in (1,966 cc) Large Unit: 260 cu.in (4,261 cc) |

| APPLICATION TEMPERATURE | 55°F (13°C) to 95°F (35°C) |

| PACKAGING PER UNIT |

Small Unit: Resin (NH) – 7.2 lbs. (3.3 kg), 0.53 gal (2L)in a 1 gal can,Hardener (H) – 0.5 lbs. (0.23 kg), 7.9 oz (0.23 L) in an 8 oz plastic bottle Large Unit: Resin (NH) – 14.4 lbs. (6.5 kg), 1.052 gal (3.98 L) in a 2 gal pail, Hardener (H) – 0.99 lbs. (0.45 kg), 15.49 oz (0.458 L) in an 16 oz plastic bottle |

| UNIT SHIPPING WEIGHT | Small Unit: 9 lbs (4 kg) Large Unit: 17 lbs. (7.7 kg) |

|

CURE TIME (APPROXIMATE. DEPENDS ON CONTACT SURFACETEMPERATURE) |

55°F – 68°F (13°C – 18°C) 48 hours 66°F – 70°F (19°C – 21°C) 24 hours Above 70°F (21°C ) 18 hours |

| POT LIFE | 30 min. @ 70°F (21°C) |

| CLEAN UP | IMPAX IXT-59 or similar epoxy solvent |

| SHELF LIFE | 2 years |

REFERENCE

For design considerations and application details please request Bulletin No. 692,

642 or contact ITW Performance Polymers Technical Services Department.

Reviews

There are no reviews yet.